Battery Optimization in Technology Solutions

Already in the specification and design phases of a development project we focuse on optimization of the energy consumption. The entire product design with choice of components, sensor technology, wireless communication, and power supply affects the energy consumption and the battery lifetime. Achieving a low energy consumption in a new technology solution will always be a compromise between hardware, embedded software, design, functionality, and the size of the battery.

Low Energy Consumption in All Elements

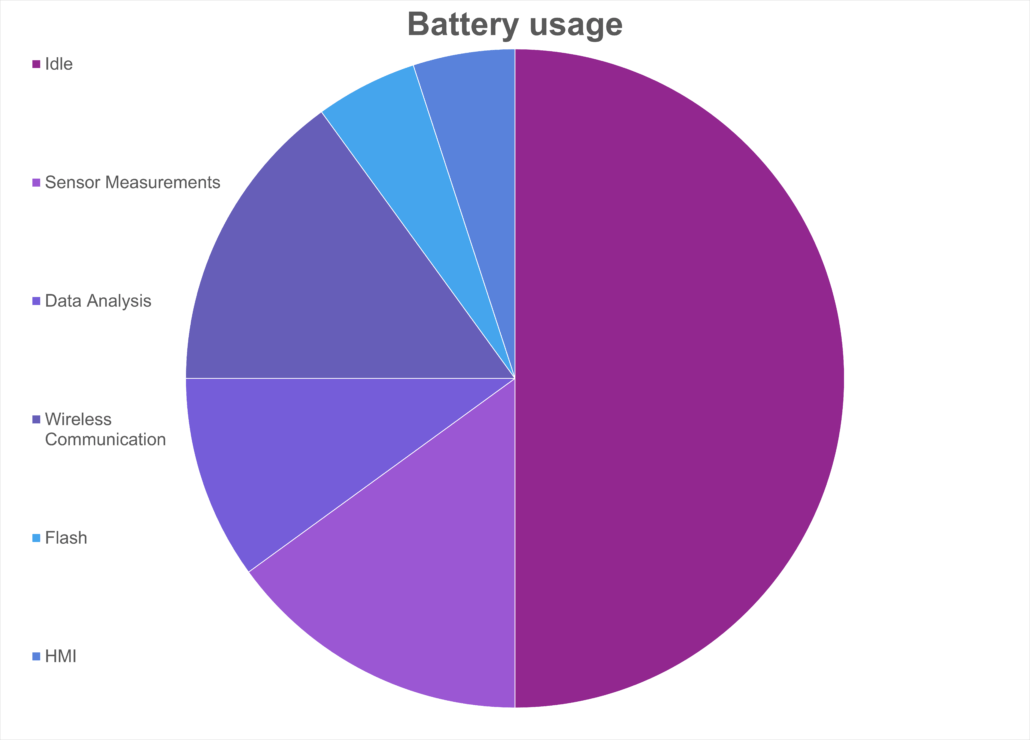

We map the energy consumption of each functional element to optimize and apply the power consumption in the right way. With a coulombmeter we measure as often and as quickly as possible the exact energy consumption in micro amperes per second for each function element and turn off unnecessary functions. We strive for the lowest possible energy consumption in all elements to maximize the battery lifetime of your finished developed product. In the Illustration you can see an example of how we work with battery optimization and the lowest possible energy consumption in all functional elements in the product solutions that we develop for our customers.

Through the years we have developed various products with a long battery lifetime, for instance the communication solution Grundfos Alpha 15-55 HWR-D for Grundfos pumps in California and the wireless device Grundfos MI 401 Alpha Reader for circulation pumps.

In all development projects we continuously use the latest technologies. For tasks that require a battery lifetime of +10 years we use modern high-quality lithium batteries. We solve other tasks with rechargeable batteries with a suitable charger, which can be wired for instance USB or wireless such as a QI charger.